NEWS FROM RATTPACK®

News and innovations from the world of sustainable packaging solutions

Susanne Kaufmann X RATTPACK® Advent Calendar - Platinum Award 2024

Learn more

RATTPACK® expands its product portfolio and strengthens its position as a full-service provider

Learn more

Fit for the PPWR - How RATTPACK® makes your packaging future-proof

Learn more

Innovation meets sustainability: new packaging solutions & awards

More experience

Now completely made of cardboard - sporting goods sustainable packaging from corrugated board

More experience

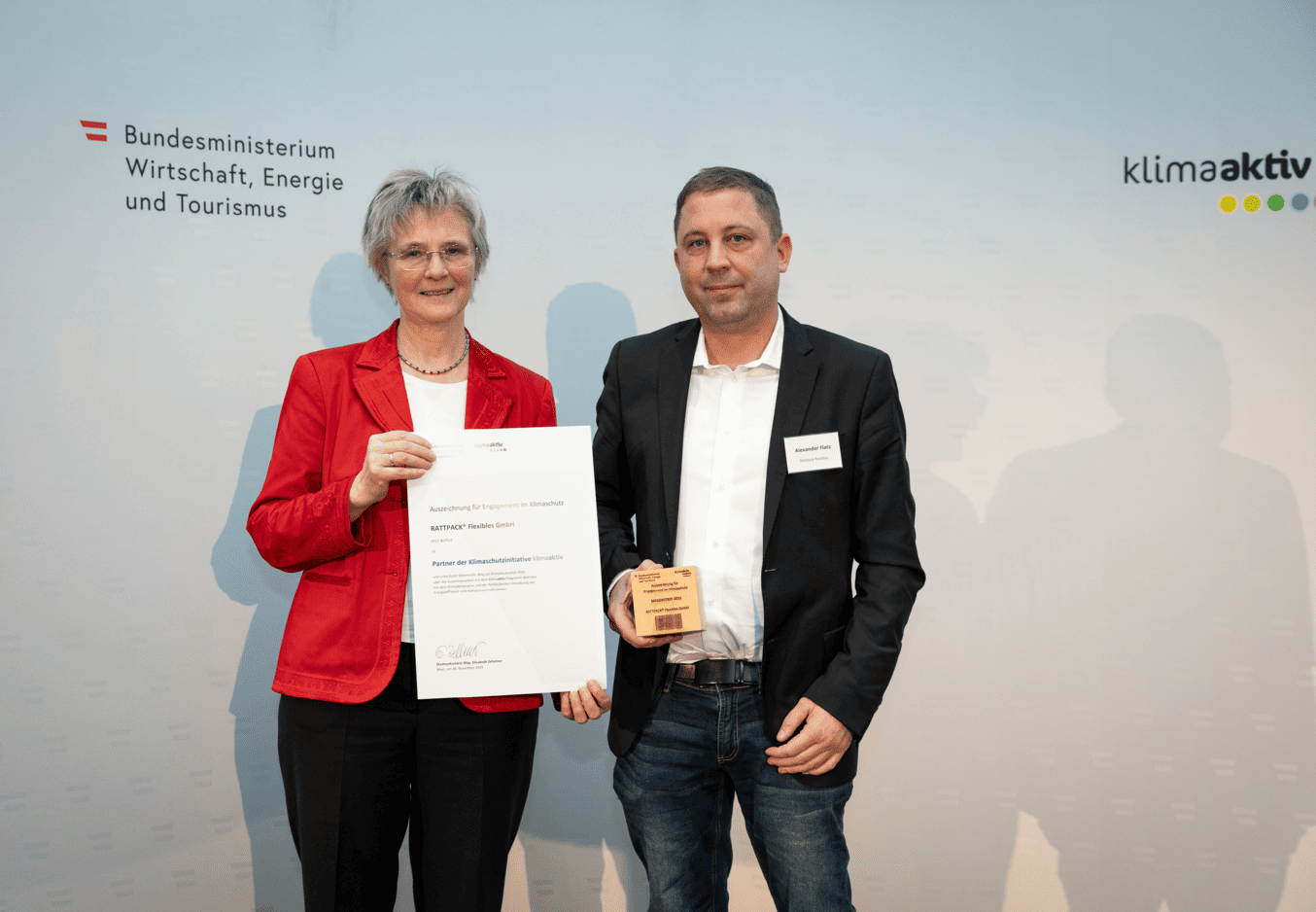

Federal Ministry awards climate-active award to RATTPACK® Flexibles GmbH

Learn more

Contact us

RATTPACK®

Achstraße 38

A-6922 Wolfurt

Austria

Fax: +43 (0) 5574 67 56-51

key topics

Labels |Wet glue labels|Commercial printing

Cardboard packaging | Cardboard trays

Packaging made from corrugated cardboard| Flexible packaging| Ratt |Packageinserts | Sachets |Clip films |Outserts| Bag in box | Shelf-ready packaging| POS displays|Folding cartons| Packaging Austria| Cardboard packaging Austria| Cardboard Cardboard displays | Cardboard displays | Cardboard Cardboard display |Flexible packaging Austria| Package insert printing Germany | 100% recyclable: POS displays made from FSC® & PEFC-certified cardboard| Sports equipment packaging made from cardboard/corrugated cardboard| POS displays in digital printing| SUP - Stand-Up Pouch / Doypack | Pharmaceutical packaging | Sachet packaging for pharmaceuticals|Squeeze pouches| Packaging company Austria | Packaging manufacturer Austria

© Copyright RATTPACK® 2018-2025 - all rights reserved. Design: KreativRaum